Cassette Deck Repair, Round 1

A lot of the equipment I work with is shared between the MIAP program and the Cinema Studies department's Film Study Center archive. As one of oldest film studies programs in the country, NYU has been acquiring movies for screening and teaching purposes for decades, so we've amassed a considerable collection in a variety of formats (though the content may not be overly unique - there's a lot of copies of, say, Taxi Driver). We also house the department's internal records, which includes a lot of audio and video recordings of lectures, conferences, and other events hosted by Cinema Studies over the years. These archival materials often offer me a sort of testing ground for equipment and resources that will end up getting demonstrated in MIAP classes. This is extremely helpful, given that archival education needs to be very hands-on, and as much as MIAP does a fantastic job of teaming up with other cultural institutions to get that direct experience, having in-house opportunities to practice what we preach is invaluable.

We've been slowly reformatting our audio cassette collection for at least a few years now on our Digital Audio Workstation (nicknamed "Bigfoot" with affection?). We run on a workhorse Tascam 112MKII cassette deck, patched into an Analog-to-Digital Converter and capturing preservation-level audio files (uncompressed WAV at bit depth of 24 bits and 96kHz sample rate) in WaveLab 8. It's slow going, since you have to capture audio in real time and we're only running the one deck, but it's a great project and there's some really cool material I hope we'll be able to make available some day.

But we hit a hitch last week when our reliable old Tascam deck broke down. Tapes would still safely rewind and fast forward, but hitting the play or pause buttons started producing discouraging sounds and a full-fledged freakout from the lights on the front panel display, after which the tape would either come to a full stop or start playing through at high speed.

The loud clattering noise and the fact that the buttons were still responding, if not functioning normally, gave me hope that this was a mechanical issue and not electronic - as I mentioned in my first post, I'm woefully inexperienced with circuit boards or sussing out electronic signal issues, but mechanical issues are usually far more visible and therefore diagnosable, if you've got the bravery and some spare parts (or creativity).

But this was nothing that I could fix as long as the Tascam was still mounted on our DAW, so my first priority was to set up the students working on this digitization project with an alternative deck while I took out the Tascam for some TLC.

We had a spare Tascam CC-222 in one of our back rooms, which was originally intended as a cassette-to-CD dubbing machine. The transport worked fine and the signal was acceptable (we're not overly concerned with preserving the quality of these tapes per se - honestly they're pretty rough recordings to begin with - but the content is super), so all I needed was some RCA-to-TT patch cables to get this auxiliary deck running. The digital meters are unideal for monitoring compared to the Tascam's analog meters, and it's essentially impossible to calibrate (there's no easy way to adjust the angle of azimuth on the playback head, for instance), but it'll do for now.

Meanwhile I did some more digging and found we had a Tascam 122MKIII sitting in storage - a model almost exactly the same in mechanical design as the 112. When I hooked up this deck it was completely unresponsive, meaning there's probably an electrical issue and I could feel pretty safe in condemning it for scrap - with luck whatever mechanical parts were broken in the original 112 would still be intact on this spare 122. Time for a transplant!

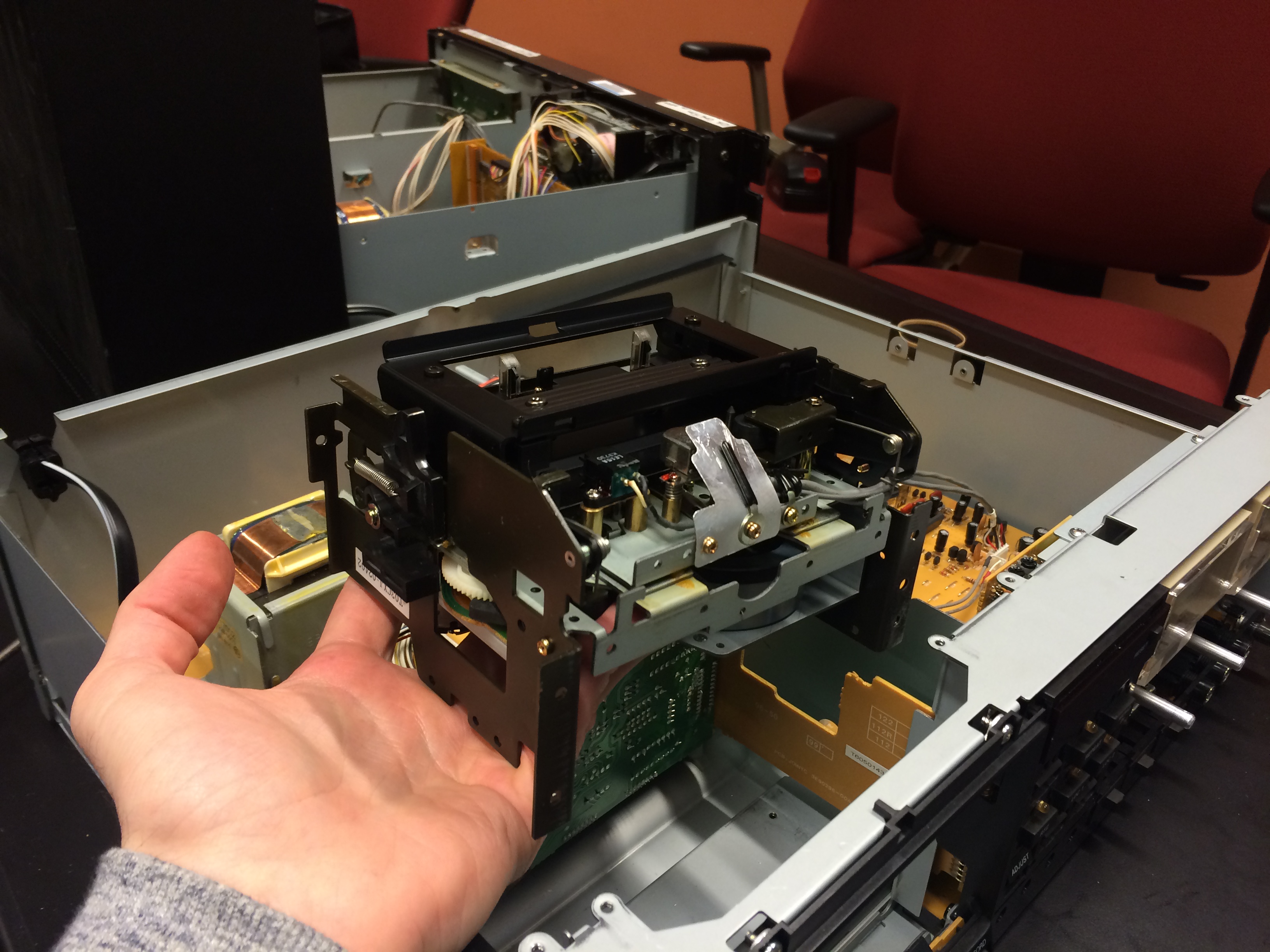

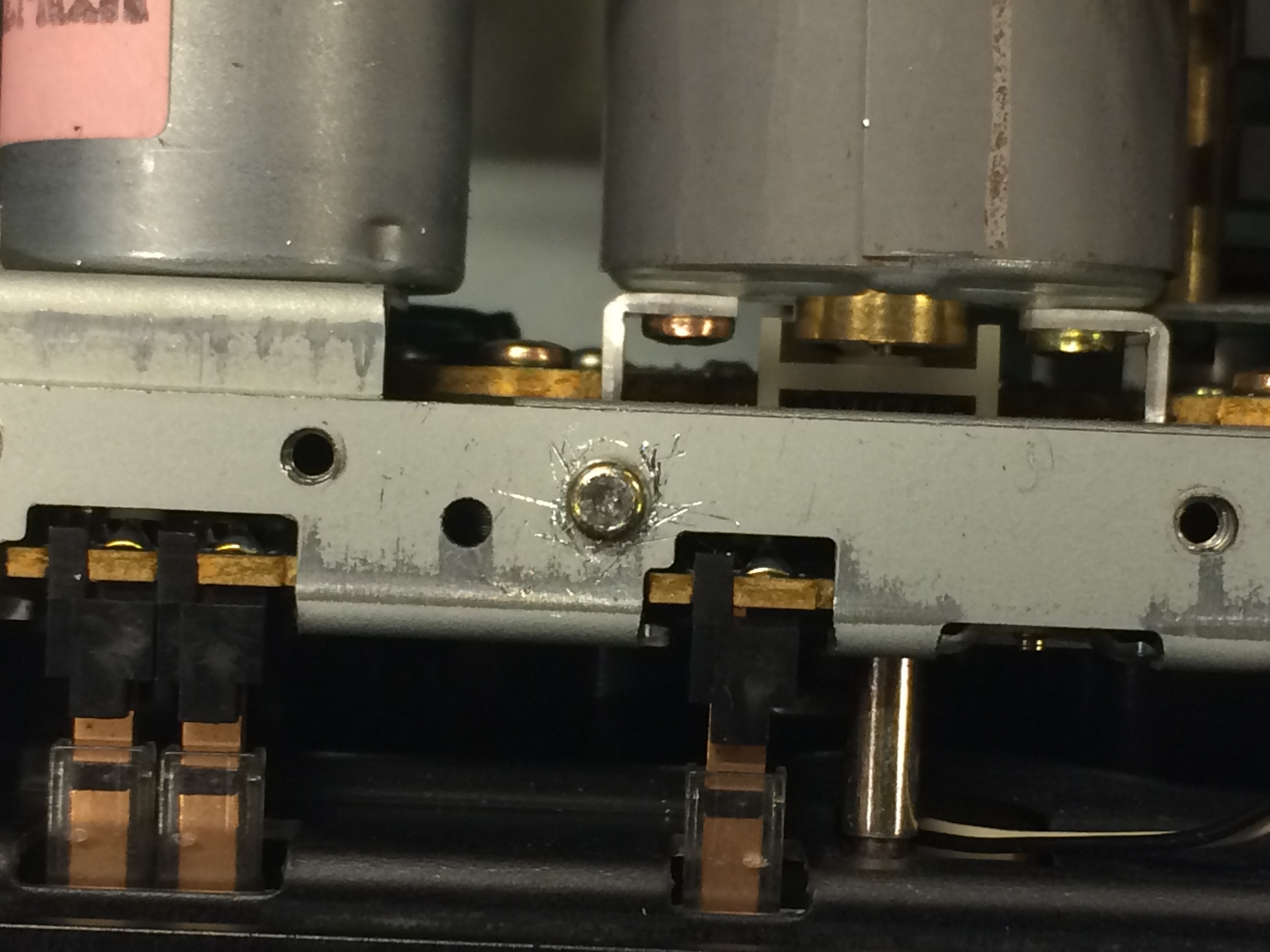

Opening up the cover on the 112, I could now visibly observe the issue with the transport unit rather than just listening. The clattering sound was mostly coming from a fitful spring, but that didn't actually seem to be the problem - tracing the motion back through the unit, I could finally see that indeed, one of the gears connecting the transport unit's motor to this spring (which in turn lifted the deck's playback head up to make contact with the tape path during normal "play" or "pause" mode) was broken. Glancing over at the 122, it had the same gear - in one piece.

So far so good - but now, how to get this gear out?

I wish I could be a little more specific here, but honestly even with a service manual at my disposal, the only strategy ahead seemed to be to start methodically unscrewing everything in sight - or even out of sight - while at least avoiding messing with the motors.

Now someone with a little more foresight might have started disassembling the backup 122 deck first. After all, that's the scrapped deck anyway, right? I could mess up that machine however I wanted and it would make no difference. But no, for some reason I plowed ahead, fiddling with the 112, apparently operating as if the broken gear was literally cancerous and the disease would spread to the other gears if I didn't get it out IMMEDIATELY.

What this meant is that halfway through disassembly, which was already a laborious process thanks to my apparently less-than-steady hands and their tendency to drop tiny screws into the bowels of the deck...

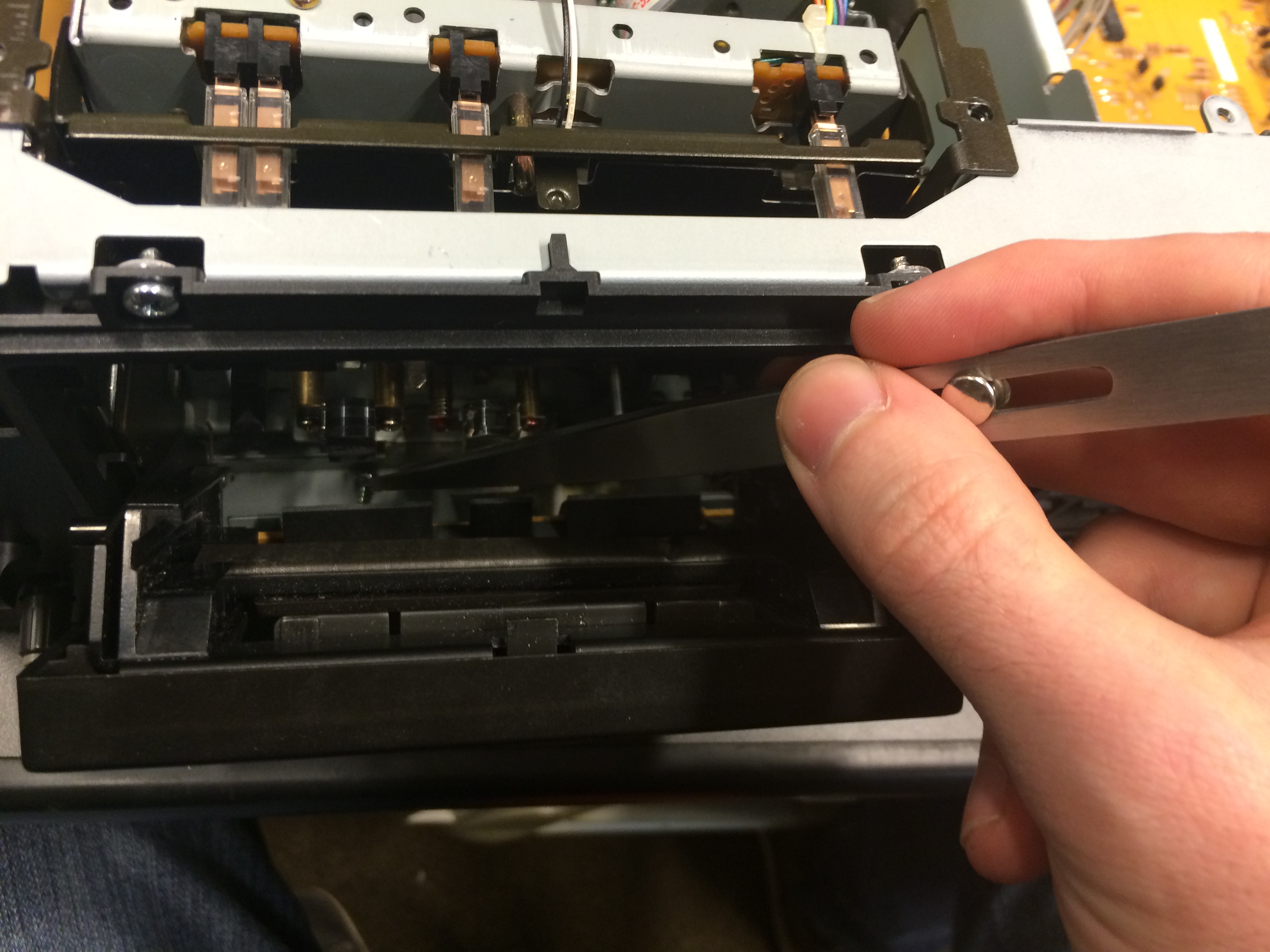

...I realized that I was entirely unsure if I would ever be able to put this thing back together correctly even if I did manage to reach and replace the broken gear. Indeed, just idly trying to fit the transport unit back into its original place in the deck, the eject mechanism was now stuck, and it was entirely unclear if the pressure pads (which sense a tape is in the deck and allow the transport buttons to work) were still functional.

So that meant a couple painstaking hours of, essentially, reassembling the deck in order to fix the damage I myself had impatiently inflicted - never mind the original problem that I had set out to deal with. Which, by the way, it turns out I couldn't have dealt with today even if I'd wanted to - one of the most essential-to-remove screws, holding the gear mechanism in place, is totally stripped, and in a very awkward position to get any leverage with a screwdriver. So the upshot of all that is a detour while I try to purchase a screw extractor drill bet set for our power drill.

Chalk that up as a learning day. At the end of it all, I at least now have a much clearer idea of how to remove the transport unit as a solo piece from the deck without interfering with its mechanical function. That is, I should be able to access the broken gear this time without taking away the machine's ability to eject or communicate with the front panel buttons. And I will do it all on the 122 first - to make sure I have a healthy heart before cutting out the bad one.